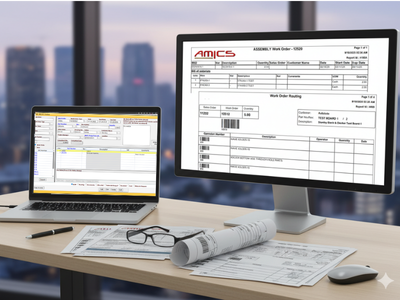

Complete Manufacturing Workflown

Work Order Module

AMICS

The AMICS Work Order Module, an essential component of our Advanced Manufacturing and Inventory Control Software, is designed to streamline your entire production process. You can easily manage the complete manufacturing workflow from start to finish. This powerful module enables users to attach a Bill of Material (BOM), define routing steps, manage process plans, accurately pick material, and efficiently receive finished goods. Furthermore, we include Add-On features like Work Order Pick and Receive and Material Charging to provide a comprehensive solution. As a result, you’ll have access to Sample Reports for work order receiving, Material Shortage, and more, which are readily available.

KEY CAPABILITIES

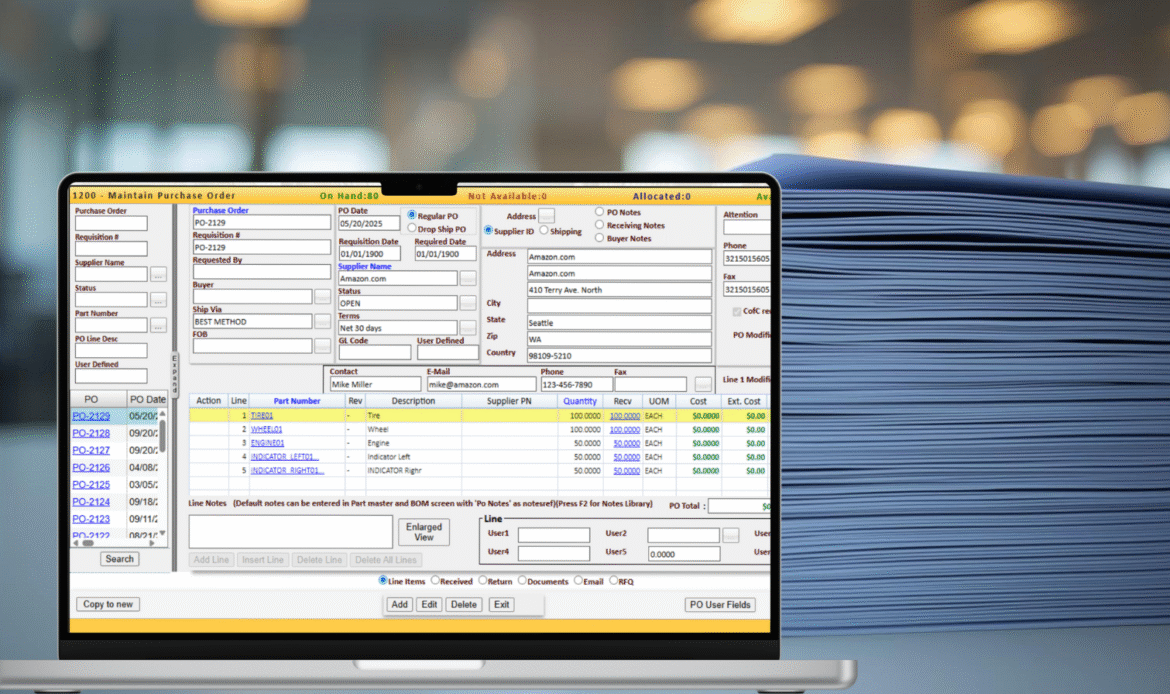

Work Order Management

The AMICS Work Order screen consolidates all key functions, enabling maximum efficiency:

First, Search effortlessly and quickly both at the order level and BOM level.

Add, Edit, or Delete work orders – all in one simple screen.

Create a work order manually or generate it directly from a sales order.

To save time, you can easily copy an existing order to a new one and edit as needed.

Attach the bill of material, routing steps, drawings, process plans, and more.

Allocate necessary material.

Pick Material and receive the finished goods.

Run reports against this order.

Add unlimited notes, or alternatively, pull standard notes from the part master.

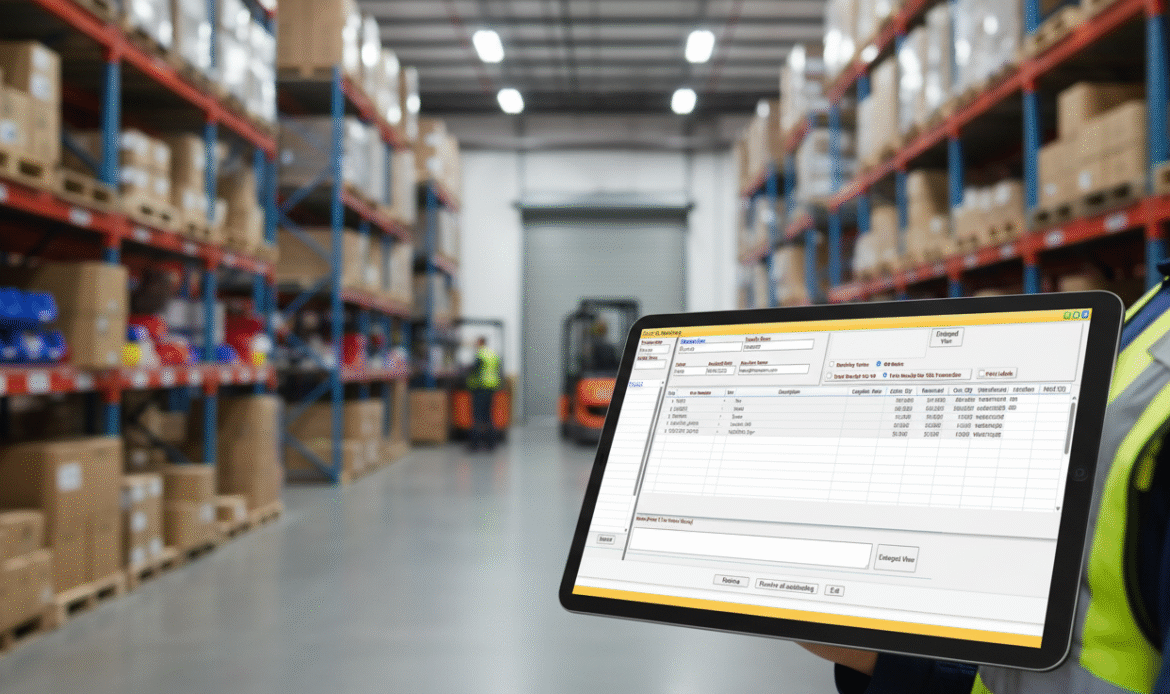

Work Order Pick

The picking process is simple, flexible, and fully controlled:

You handle material picking or material charging for a work order from the same work order screen.

Choose the BOM line item and charge material using either FIFO (top to bottom) or a Random method.

Optionally, allow the system to pick in a strict FIFO manner for all items.

Importantly, you can undo any material charge at any time, ensuring accuracy.

Record Scrap on already charged material.

The transaction log shows a complete history of lot and serial numbers, consequently, you can easily trace material consumption.

Multiple specialized reports are available.

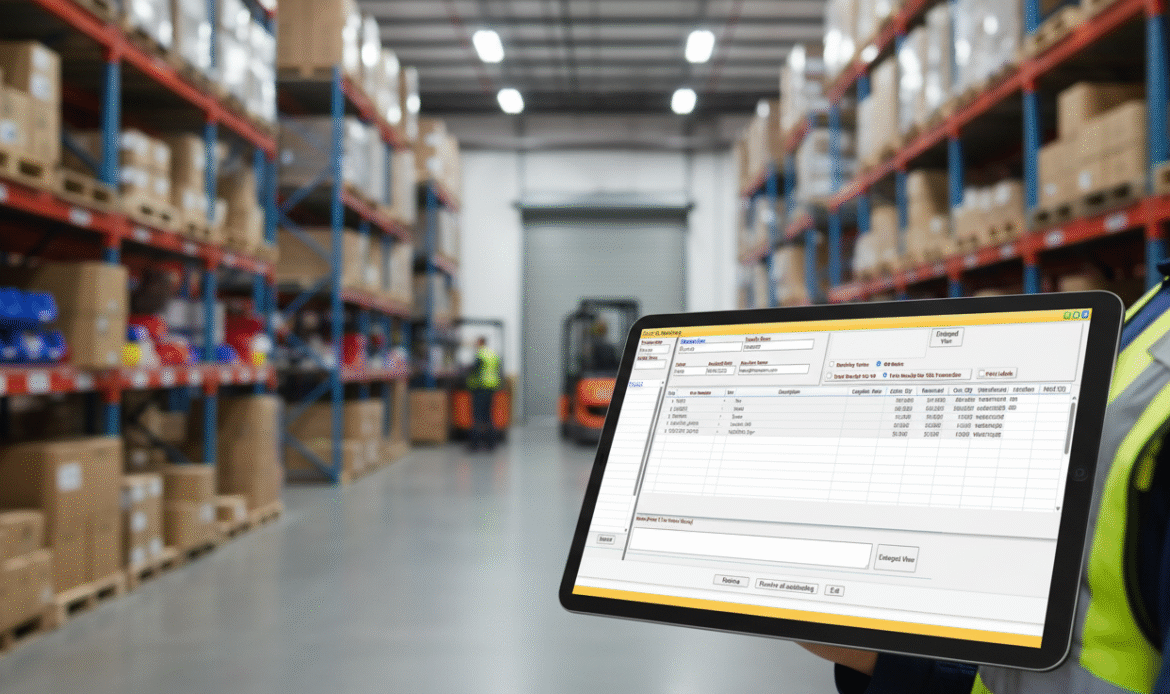

Work Order Receive

Receiving finished goods is fast and accurate:

Users receive all completed quantities from a work order.

Multiple options manage the material consumed during the work order process.

You can receive multiple lots and enter the batch, lot, or serial numbers.

View received items and details on the receipt directly from the work order screen.

Consequently, the system maintains a transaction log on all transactions for full trace-ability.

Reports

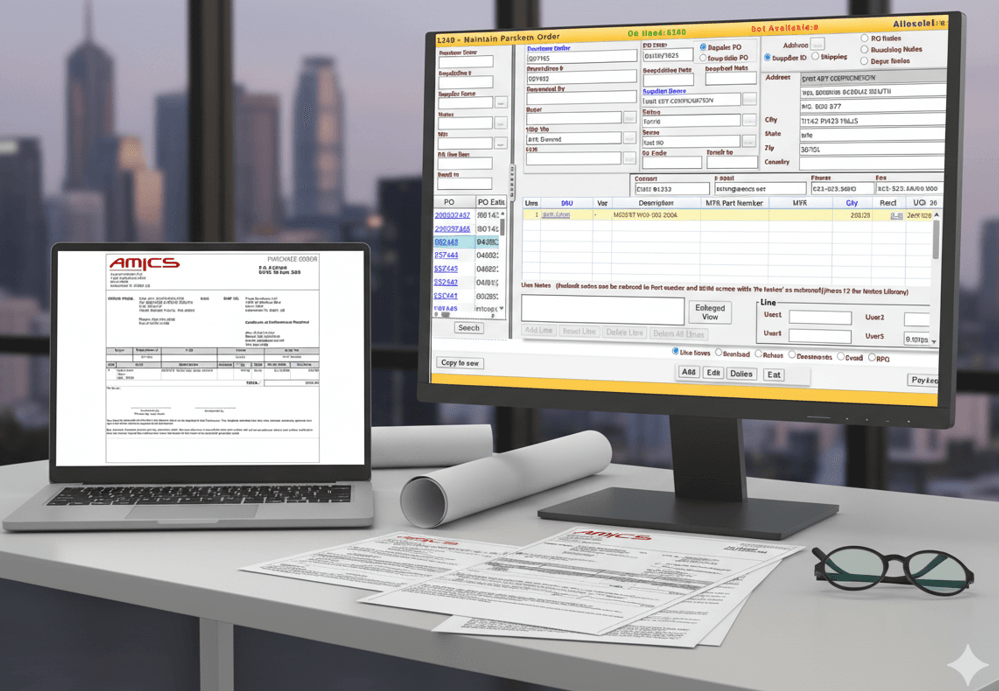

Robust reporting gives you total visibility into your production. The AMICS Work Order Module provides:

Assembly work order reports complete with BOM and routing steps.

Search for a work order and print comprehensive reports for that PO.

Specifically, the module includes Work Order receiving, Picking Labels, and bar-coded reports.

Work Order Pick List – available in both summary and detail formats.

Material shortage reports per work order.

For complete auditing, the system generates transaction log reports for history transactions, which is critical for serial and lot trace-ability.

Open order report – summary and detail sorted.

Therefore, the AMICS Work Order Module is the trusted partner for manufacturing, warehousing, and government agency companies that want to optimize operations, improve customer satisfaction, and stay competitive in a demanding market. This solution is fully integrated with our core Inventory Module to ensure seamless data flow across your entire business.

Ready to optimize your operations? Contact us today to schedule a demo.